CONVERT YOUR CROWN XLi-SERIES CL-A/B AMPLIFIER INTO A LOW FREQUENCY, ACTIVELY FILTERED, 2-CH BAND-PASS BASSHORN AMPLIFIER

INTRODUCTION

North Reading Engineering has designed and is providing a 2-channel, band-pass, active filter board (shown installed in the photo above, right) for installation in any of the Crown XLi-Series, Class A/B, rail switching amplifiers. With the filter installed the extremely popular Xli-Series amplifiers become super low distortion, high power, actively filtered amplifier packages. The filters are cascaded Sallen-Key designs based on the Texas Instruments TLE2074CN quad op-amp package. The filter sends a precisely defined, band-pass spectrum of bass frequencies to each channel of the amplifier. Two filter configurations have been developed specifically for the Klipsch Jubilee and Klipschorn bass units. Front panel potentiometers on each channel of the amplifier provide a convenient method of setting the output of each channel. Thus, while in use, the output of either the left or horn can be adjusted independently.

Printed circuit boards are top quality and manufactured in the USA. Boards are assembled using components from best US and Japanese suppliers and installed and tested by North Reading Engineering.

So if you're using your old school Crown Xli800, 1500, 2500 or 3500 to power your low frequency horns or direct radiator system and wish to convert to active, integrated filtering this mod gets it done. Also, tailoring the filter to other low frequency loudspeaker system requirements is very easy to do and, for two way systems, the filter can be designed to output a low frequency band-pass frequency range to CH1 and a high-pass frequency range to CH2.

HIGHLIGHTS

Bass Horn Amplifier

-

Klipschorn and Jubilee bass horn designs available.

-

Each channel outputs a fourth order (24dB/octave) band-pass response based on cascaded unity gain Sallen-Key filter topology.

-

Band-pass response provides rejection of low frequency "noise" due to horn unloading, turntable rumble, enclosure and room spurious responses.

-

Low frequency rejection greatly improves bass "clarity" and subwoofer integration.

-

On-board +/-15VDC regulated power supply rails based on On-Semi MJE350/340 Medium Power Transistors.

-

Input sensitivity @ 300Hz and TLE2074CN package: 1.0VRMS (1.4V rear panel setting) and 0.5VRMS (0.775V rear panel setting)

-

Extremely low %THD over the pass-band of the amplifier.

-

Rejection of high frequencies allows amplifier to run cooler.

-

Filter can be easily bypassed for full range amplifier output without having to remove the board.

-

High quality film and C0G MLCCs capacitors used throughout.

-

Pair of 14 DIP sockets for op-amp removal and replacement.

-

Eliminate passive network losses, extreme part counts and high cost associated with steep slope passive nets.

-

Portable amplifier/filter solution based on Class A/B type amplifier topology.

-

Independent volume controls for each channel with Crown Fault, Signal and Clipping LED indicators.

Other Configurations

-

Customizable for any user defined CH1 or CH2 band-pass requirements.

-

Filter can be designed to provide LF band-pass output to CH1 and HF high-pass output to CH2 (two way systems).

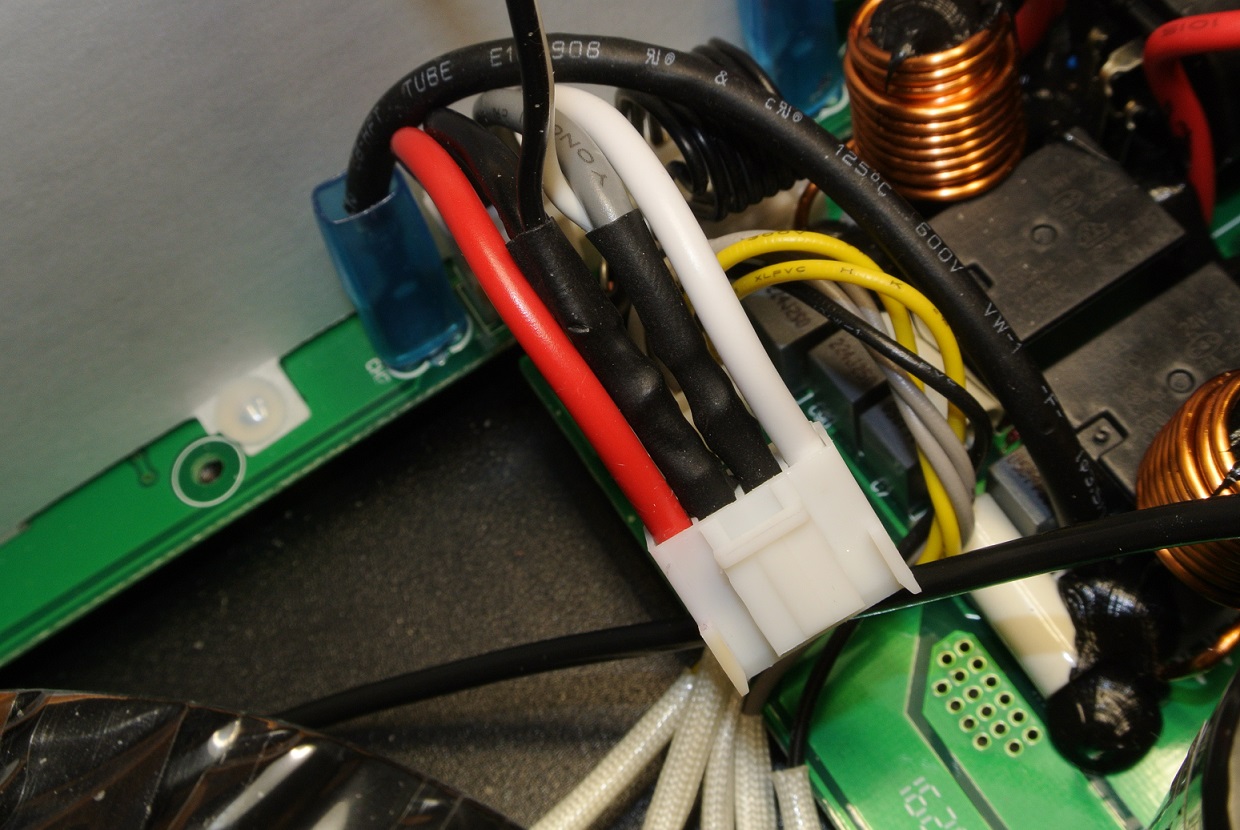

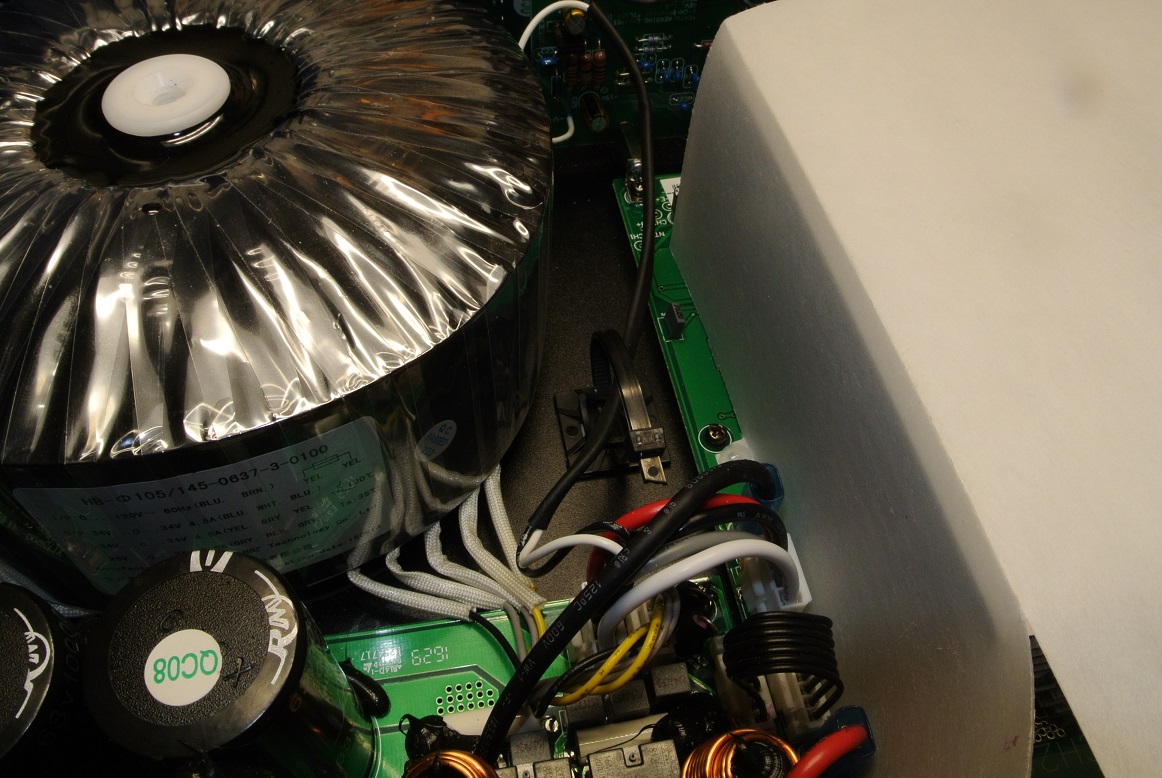

SYNTHESIS

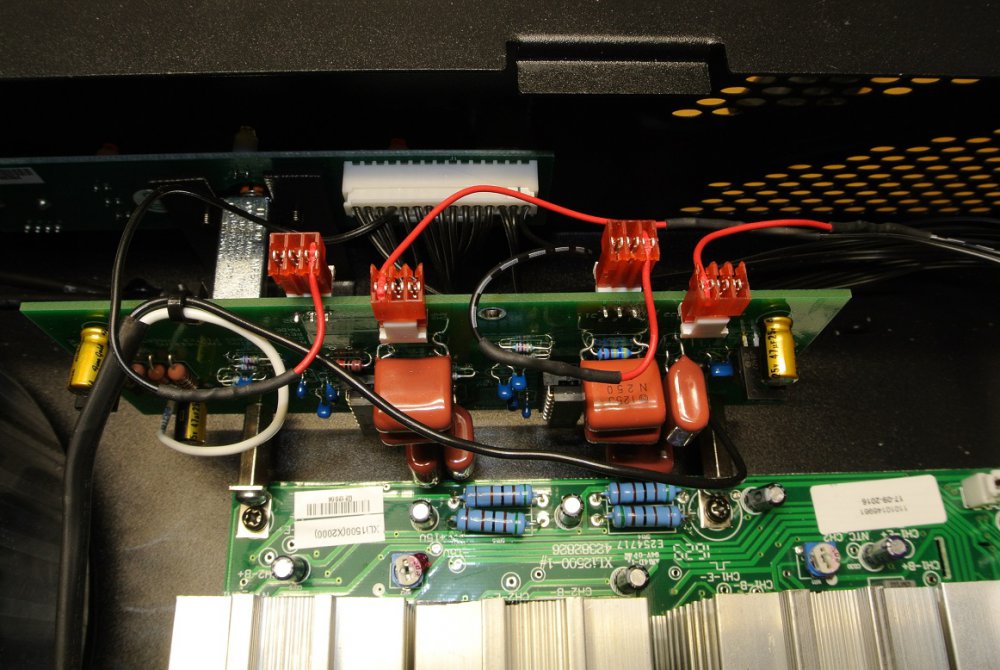

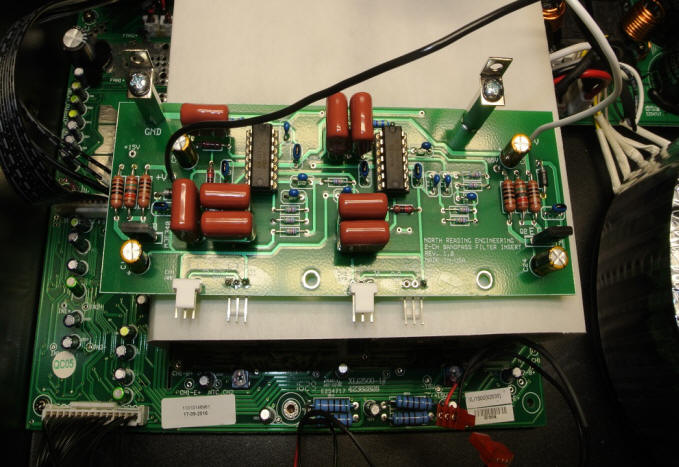

The photograph below left (top on hand held) is the filter prior to installation. Positive (black) and negative (white) power supply leads are tapped off the low voltage rails (VL+/-) of the main power supply to provide power to the filter's on-board regulated power supplies. The two channels draw about 25mA of current from the lower rail. The board is mounted to the chassis using the L-brackets shown. Small stand-off washers (not shown) are sandwiched between the L-bracket and amplifier PC board.

Filter ground is accomplished by the left mounting bracket which connects to one of three dedicated ground connections identified on the amp board. Note Panasonic polyester caps (large brown caps) for high-pass filter sections, Nichicon Fine Gold on the power suppliers. Small signal connections from the amplifier balance to unbalance front end op-amp are made using MTA pin-type connectors.

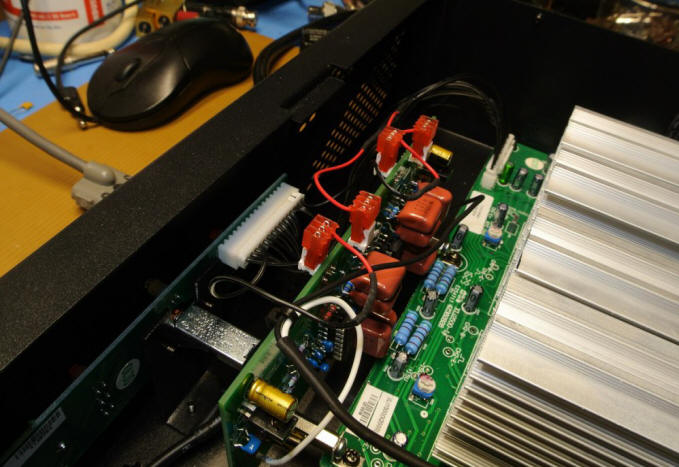

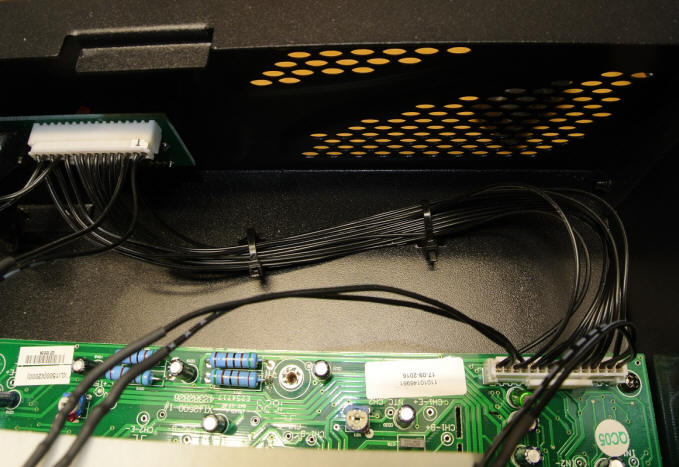

The photo at right (bottom on hand held) shows the board installed in an XLi1500 with small signal connections made. Twin fans draw cooling air across the output section heat sinks. Note with the filter installed, there's plenty of room to allow cooling air to be pulled from the front panel.

MEASUREMENTS

Bass Horn Applications

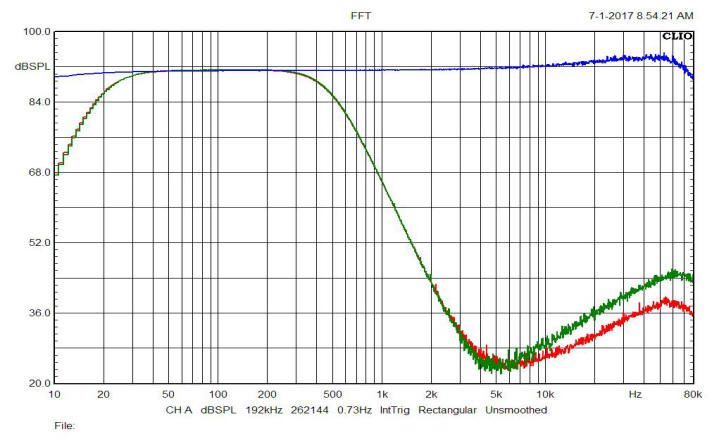

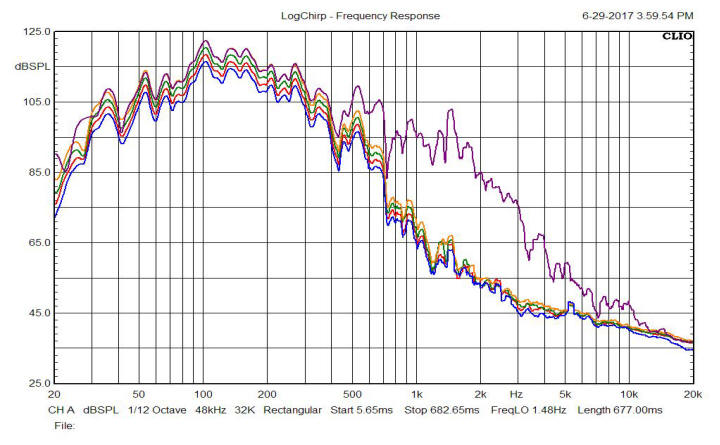

The amplifier response with the Klipschorn bass horn filter is shown in the plot below left (top on hand held)) using a 4 Ohm power resistors as a load. TLE2074CN op-amp. The FFT analyzer is a CLIO 24-bit FW with input signal cross-correlated with the output and is capable of precise measurement to a little over 80kHz. The analyzer senses the signal across the load resistor. As shown in the plot the amplifier responses (green and red) is a band-pass response with 24dB/octave attenuation above and below the -3dB corner frequencies. For Klipschorn users the filter is set for a -3dB high frequency corner of 413Hz whilst the -3dB low frequency corner is 28Hz. The blue response is the amplifier with the filter bypassed.

Note the amplifier is capable of output to well below 30Hz which, without filtering, will modulate the unloaded Klipschorn woofer cone resulting in low frequency "noise" and spurious resonance.

The next plot at right (bottom on hand held) is the acoustic response of a factory Klipschorn bass unit, with K33E woofer, measured both without the filter (purple) and with the filter engaged and measured at four different potentiometer settings. For applications where a subwoofer is used, the low frequency corner can be increased to a higher frequency by suitable selection of the high-pass section capacitors.

The ability to individually tailor the gain of the bass drivers while listening to the system provides for a degree of flexibility that's not possible using passive networks. Also, to realize the steep slopes developed by the cascaded Sallen-Key architecture, a passive filter network configuration would require a "wheelbarrow" of capacitors, inductors, resistors.

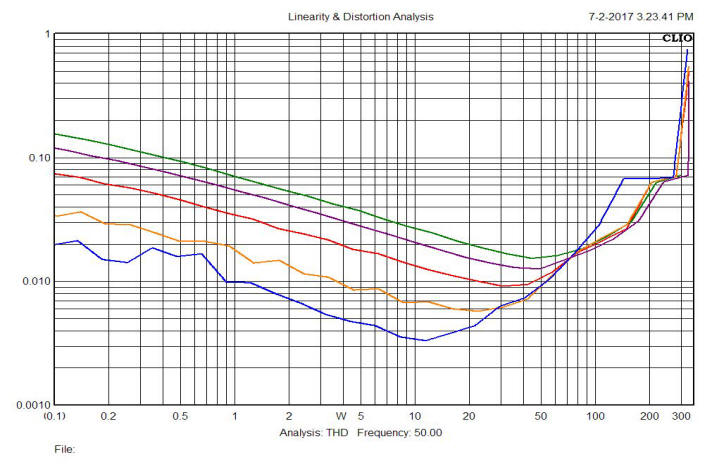

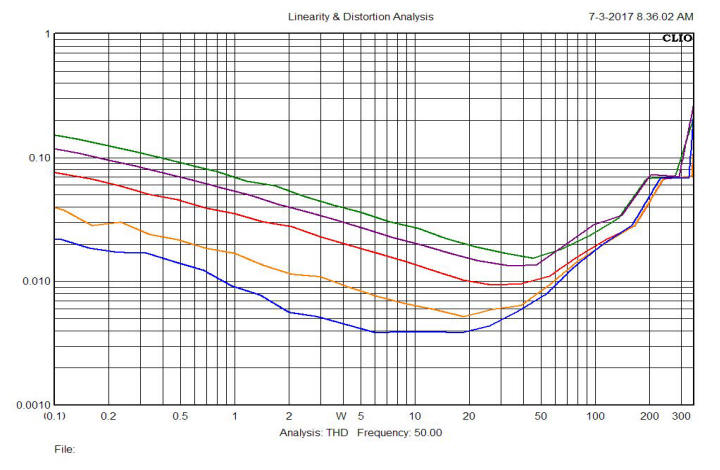

% Total Harmonic Distortion

%THD of the amplifier with the integrated filter is measured spanning five test frequencies across the pass-band is shown below (from top to bottom: 400, 300, 200, 100 and 50Hz). Amplifier used in this test is an XLi1500, load is 8 Ohm power resistor. Left (top on hand-held) is AD713 op-amp package, right (bottom) is the lower cost Texas Instruments TLE2074CN. Maximum voltage across the load resistor in this test was measured to be about 54VRMS for a maximum power of approximately 350W. As is evident in the plot, %THD from about 100mW to nearly 300W is remarkable at <0.2%. At typical listening levels the distortion produced by the amplifier is essentially negligible.

Two-way System Applications

The filter components are selected to provided a low frequency band-pass output to CH1 and a high-pass output to CH2. The filter is configured to drive a bass horn or direct radiator bass driver off CH1 and a mid-high frequency compression type horn off CH2. The crossover is typically 600-800Hz in applications like these. Contact North Reading Engineering.

HARDWARE PURCHASE

Kit includes the assembled filter with TLE2074CN quad packages installed, assembled connectors, required wires, mounting hardware, shrink tubing and detailed instructions. Kit installation is recommended for skilled builders only and requires temperature controlled soldering, heat gun, stripping fine gauge wires (26 AWG), splicing, discharge wands and test gear. Quality wire stripping tools, soldering skills and a working knowledge of high charge capacity power supplies and ESD sensitive devices is required.

North Reading Engineering amplifier installs include performance data emailed to customer.

For customers that wish to build there own filters or experiment with unity gain, cascaded Sallen-Key topology, bare PC boards are available and a schematic provided. For non-Crown installs, an input buffer is required and designs for those are available as well. Shipping not included in prices, quantity discounts available. And, of course, customers must ship amps to North Reading Engineering for installations.

PRICING

Klipschorn/Jubilee Bass Horn filter + Installation: $250

Klipschorn/Jubilee Bass Horn filter kit: Customer installs assembled filter: $130

Customized band-pass or two-way filter + Installation: $250

Bare filter board w/DIP sockets, pin connectors and leads attached: $39

BUILD GALLERY

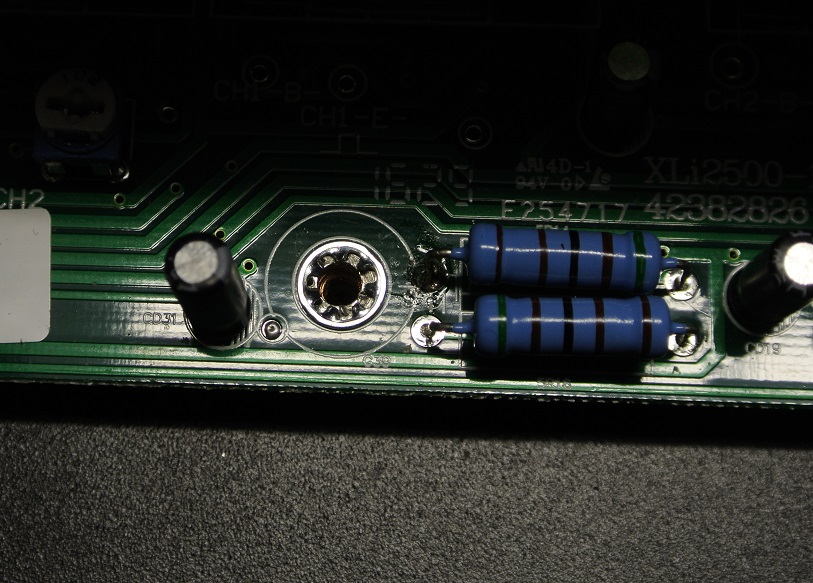

Voltage taps off lower power supply rail connector, factory gray is VL-, black VL+. Note heat shrink tubing over splice locations, 22AWG leads provide power to filter.

Internal tooth lock washers located between amplifier PC board and filter mounting bracket. Ground connection to amplifier chassis is at right (bottom on hand held).

XLi small signal ribbon cable, #26AWG. MTA connectors use #22AWG.

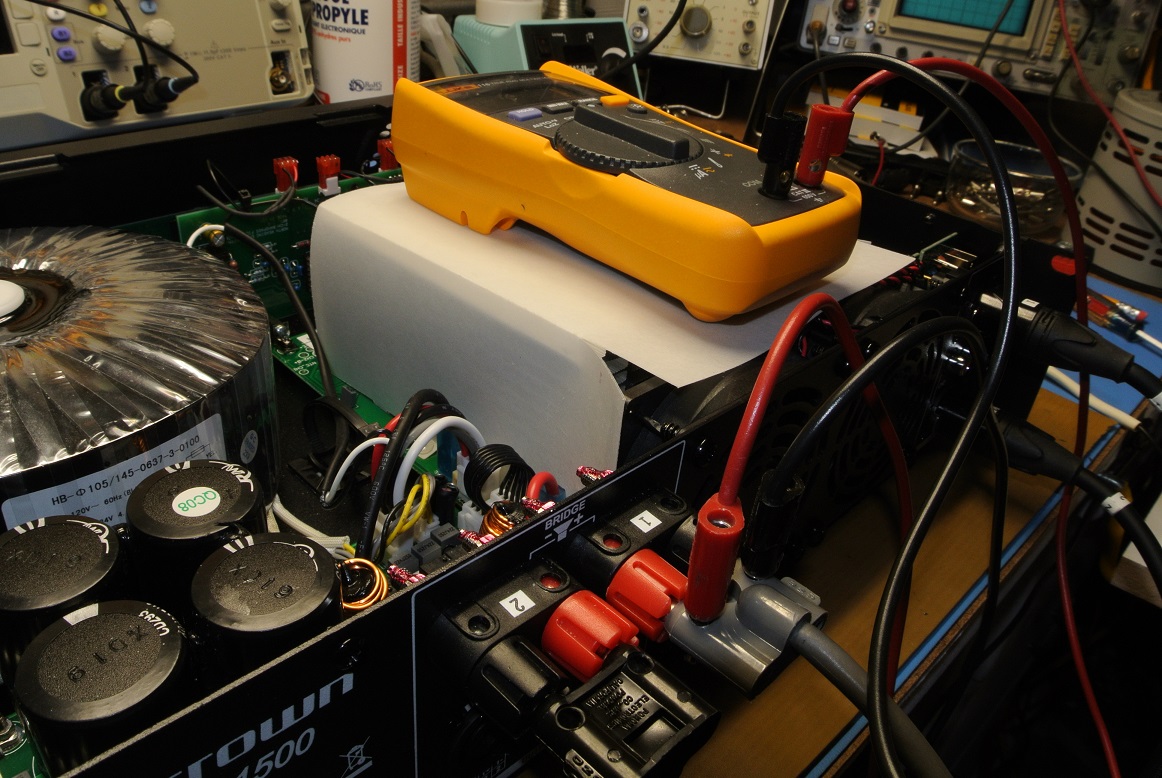

Photo below left (top on hand held) shows leads from main power supply to filter board secured by anchor. On right (bottom on hand held) is final testing of modified amplifier.

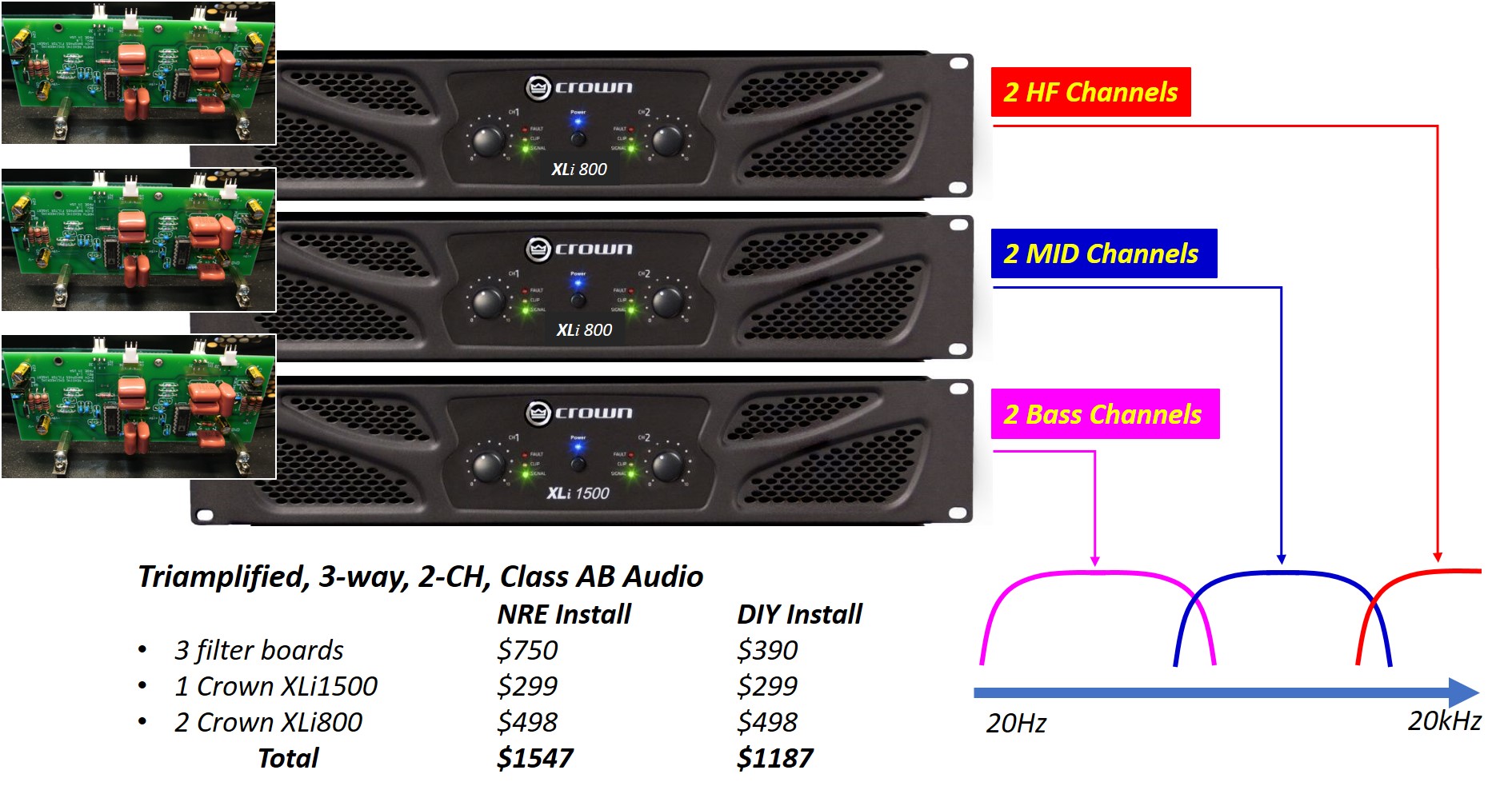

One possible configuration of Crown XLi Series triamplifier stack with active filtering shown below.

Website and contents property of North Reading Engineering, North Reading, MA 01864 USA. No part of the above may be copied and published, in part or in total, without permission. © 2017 John Warren