ULTRA-LOW DISTORTION, EMI/RFI HARDENED, ACTIVE 2-CH BUFFER / 3-WAY SPLITTER FRONT END FOR AMPLIFIER BUILDERS

INTRODUCTION

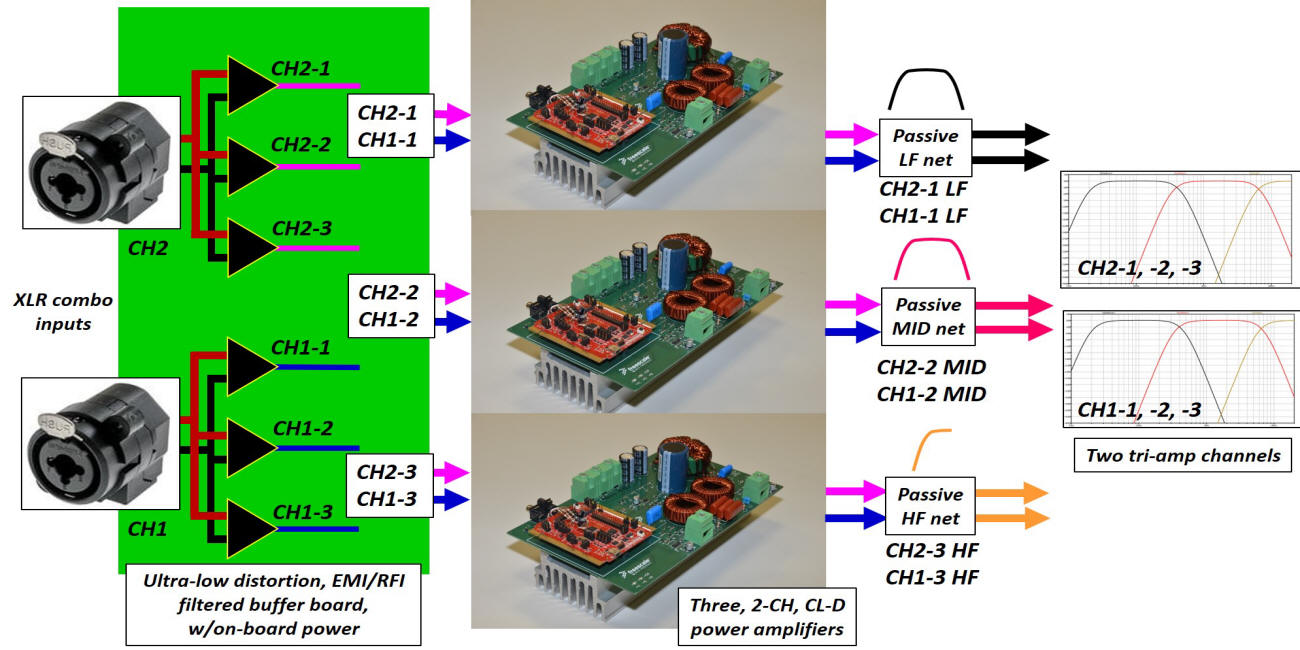

Described here is a 2-channel stand-alone buffer module that accepts a small signal input from a typical 600 Ohm source impedance and splits each channel into three, non-inverted, independent and (essentially) identical single-ended output signals, each capable of driving an amplifier, active filter, meter amplifier and so on. The module can be used as a splitter for a 3-way, tri-amplified loudspeaker system where each signal is sent to a dedicated amplifier sized for low, mid and high frequency drivers. The figure below illustrates the idea. Passive nets for low, mid and high frequencies are used to provide large signal filtering after the amplifier outputs. Although the figure shows CL-D "chip" type amplifiers, audio amplifiers of any type will work. Note also the power supplies for the components are not shown.

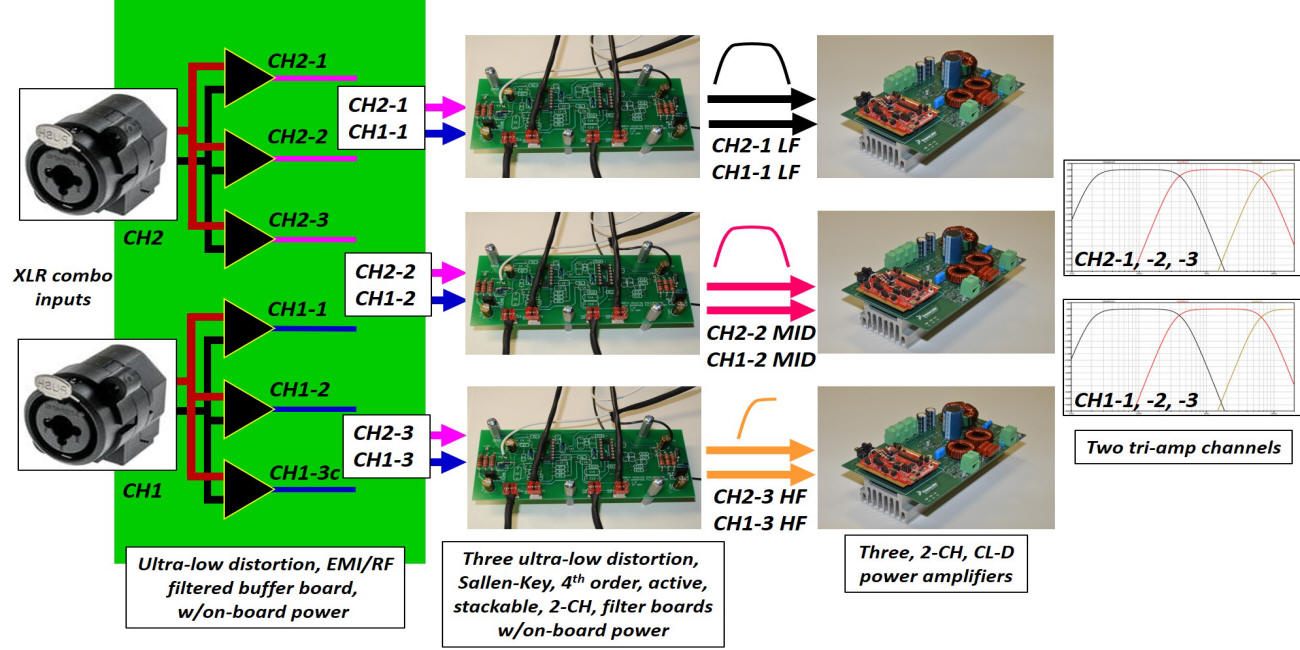

An alternative filtering scheme to the above (and a preferred approach) is to employ active filters between the buffered signals and associated amplifiers. That concept is shown below and, as before, three amplifiers are used and sized for the low, mid and high frequency drivers in the system. Note that North Reading Engineering has designed very low distortion Sallen-Key evaluation module that is ideally suited for providing builders and engineers the active filtering in this setup.

With the addition of level controls (i.e. attenuator pads) the module can also be used as an ultra-low distortion preamplifier or, by increasing the gain of the op-amps, a super quiet headphone amp.

TECHNICAL DESCRIPTION

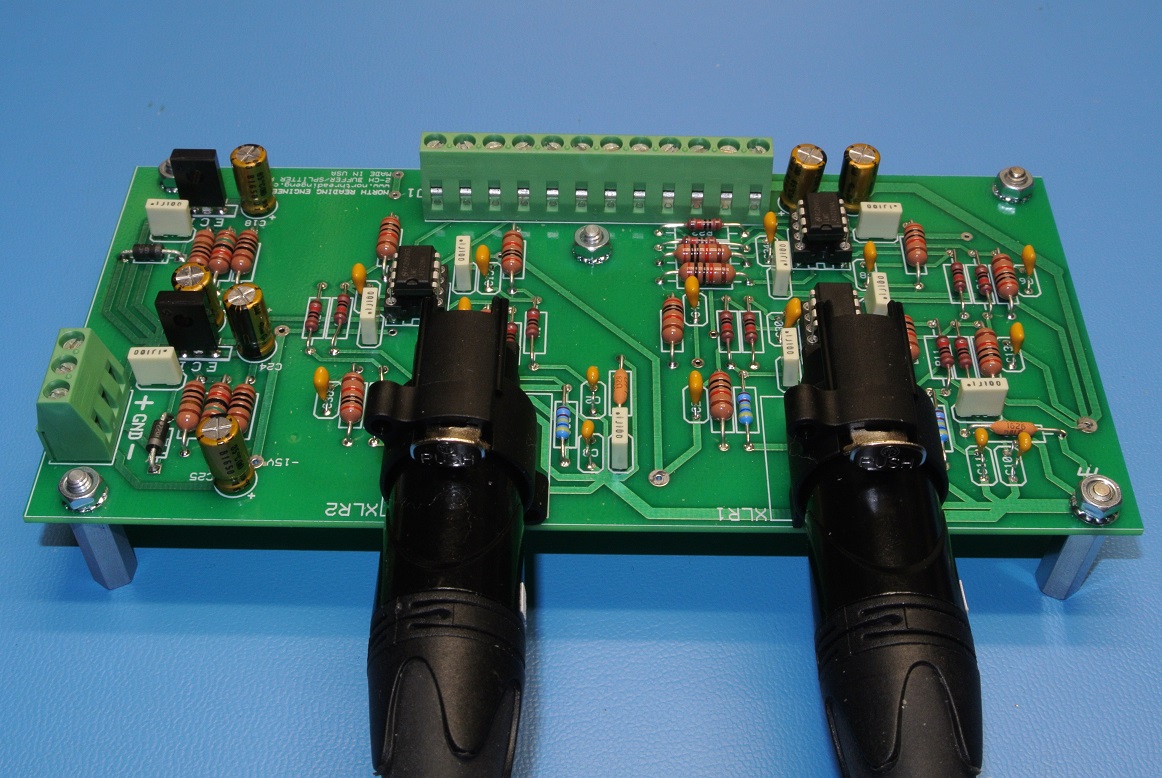

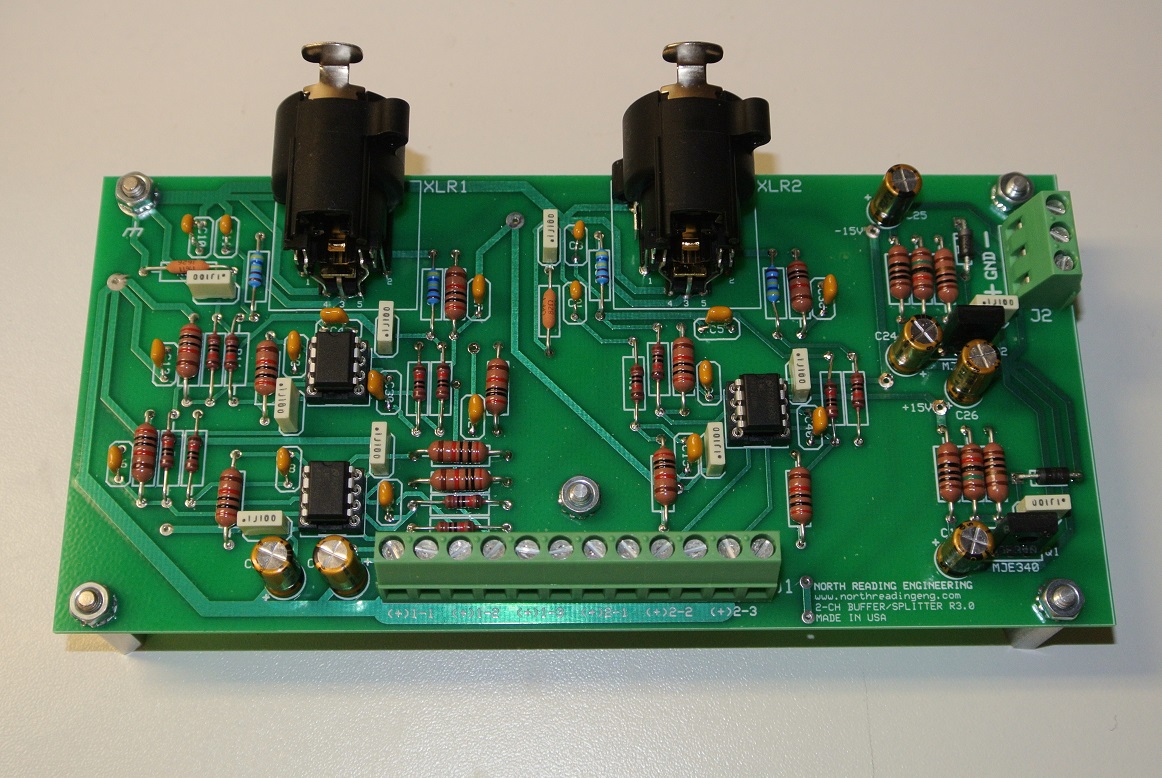

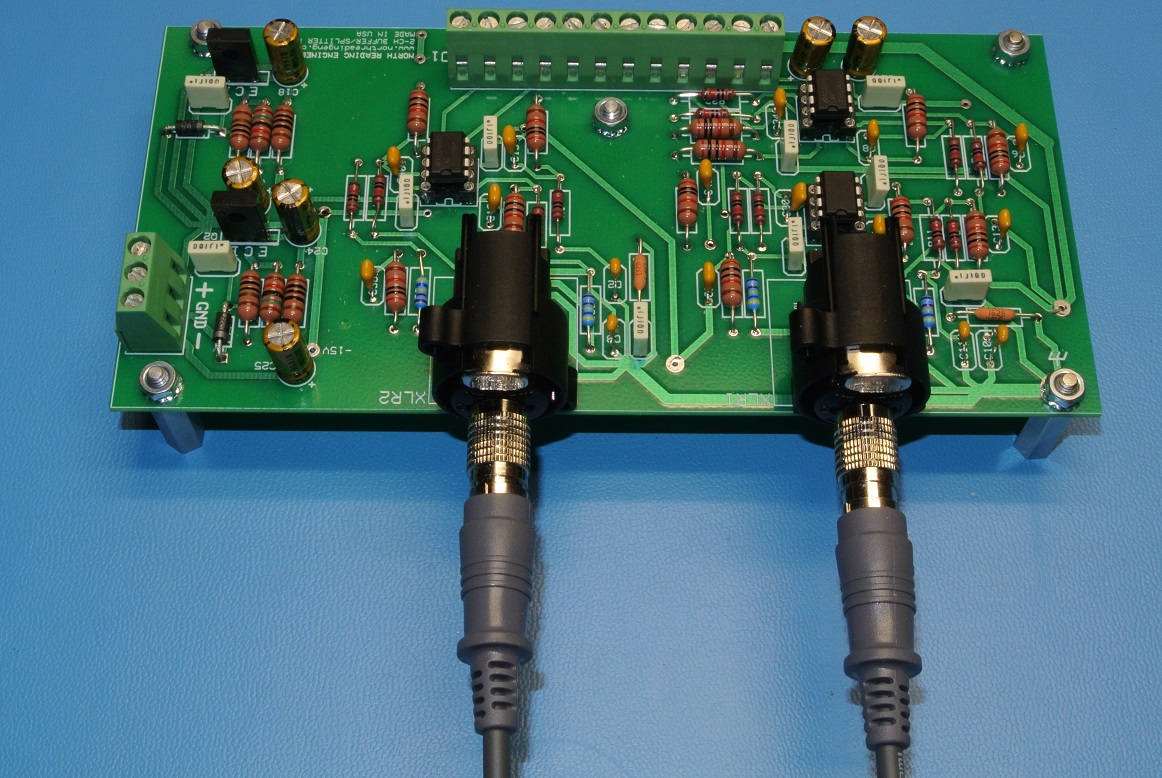

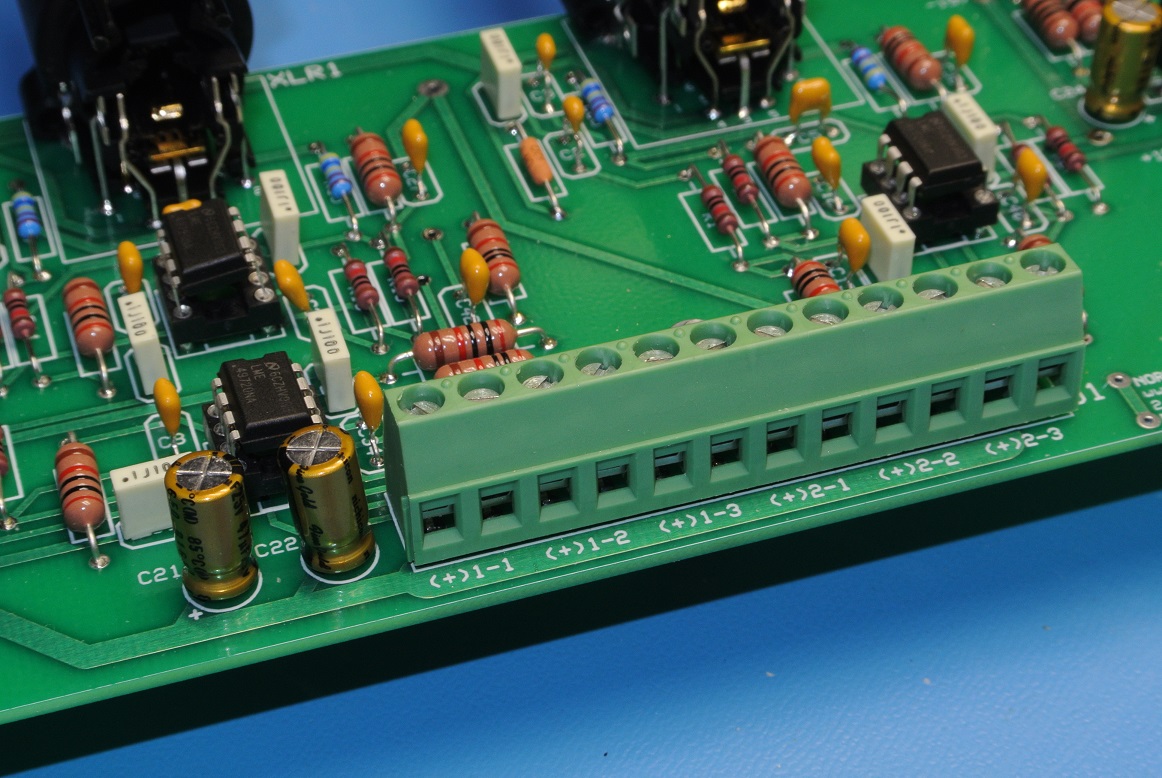

The buffer/splitter module is shown below. XLR combo connectors have been selected to provide users with both balanced XLR/TRS inputs or, with the adapters shown in the photo, un-balanced RCA inputs. Power supply +V, GND and -V connections are made using a 3-postion, screw clamp, terminal block. Single-ended outputs (6 total) are made at the 12-position terminal block (both terminal blocks are Phoenix Contact products). Op-amp packages are installed in Mill-Max sockets which allows for replacement of damaged devices or substitutions (the LME49720 may be EOL in 2018). The LME5532 for example, is an excellent alternative package for driving low impedance loads (most audio amplifier inputs have input impedances that exceed 10k Ohms).

The boards are fabricated in the USA. Pb-free, RoHS compliant assemblies are also available.

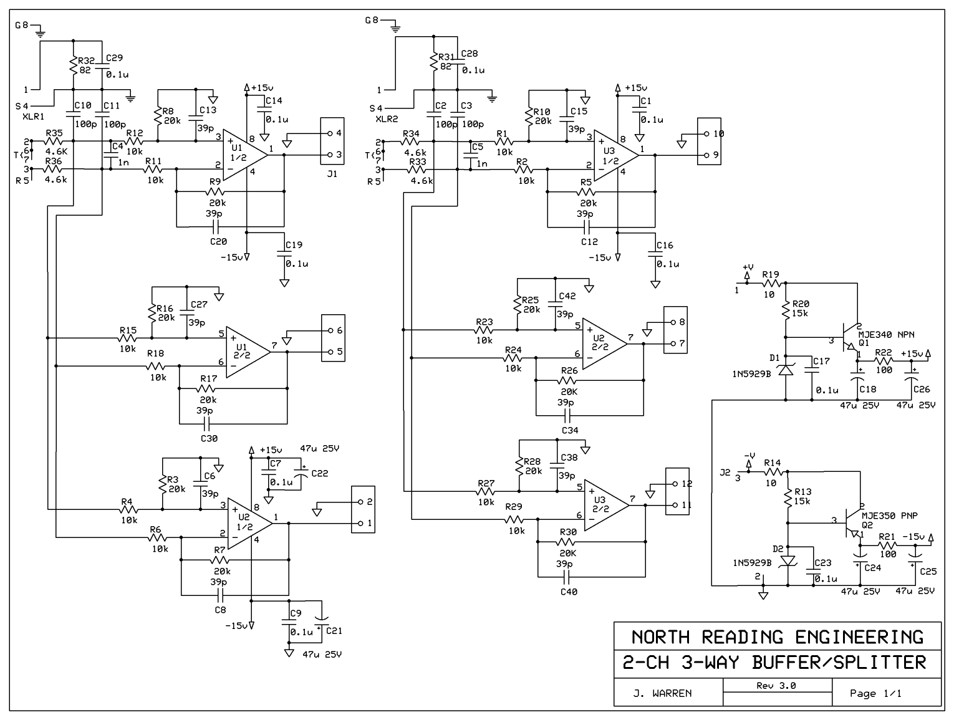

The schematic for the design is shown below. The front end of each channel is configured with a general purpose, common mode/differential mode EMI/RFI filter useful in environments with high levels of transmitted noise. Looking at the XLR1 front end (the XLR2 front end and layout is identical), the complimentary RC pairs R35, C10 and R36, C11 provide common mode input rail filtering whilst R35, R36 and C4 provide differential mode filtering. Circuit common mode rejection (CMR) depends on the time constants of the complimentary RC pairs be matched otherwise reductions in CMR are realized. The front end design requires precisely matched resistors. With selection, all metal film resistor values are matched to better that +/-0.05% tolerance from +/-1.0% lots. Resistor temperature coefficients of 15PPM/°C are standard.

Using the feedback scheme shown in the schematic, bandwidth measurements with LME49720 dual op-amp package evidences a -3dB frequency at 37kHz. The measurement is made with each output pin with RL=10k Ohm. Input impedance is 16k Ohms measured with a balanced input source impedance of 660 Ohm. Differential gain of the buffer (Ad) is approximately = -1.2dB.

Capacitor C4 reduces differential EMI/RFI signals on the inputs. Differential mode -3dB frequency is about 60kHz. Both C10, C11, XLR shield (Pin 1) and the XLR connector body shunt to chassis ground. Cable shield drain wire from Pin 1 sinks to chassis ground by a "hybrid", parallel RC filter. The chassis ground connection is identified on the board and is independent of the small signal 0V circuit reference. Here, an isolated, linear +/-24VDC supply (Bel Power Solutions HAA24-0.6-AG) is used to drive the board. On-board, regulated +/-15VDC (unloaded) supplies provide power to the 6 op-amps. The on-board supply requires an external power supply capable of providing between +/-18 to +/-60VDC. Although a dedicated power supply can be used to drive the board, taps from the output stage rails of the amplifier supply is also a possibility. MJE340G/350G, 0.5A complementary power transistors in TO-225 packages are used in the supplies.

PERFORMANCE PLOTS

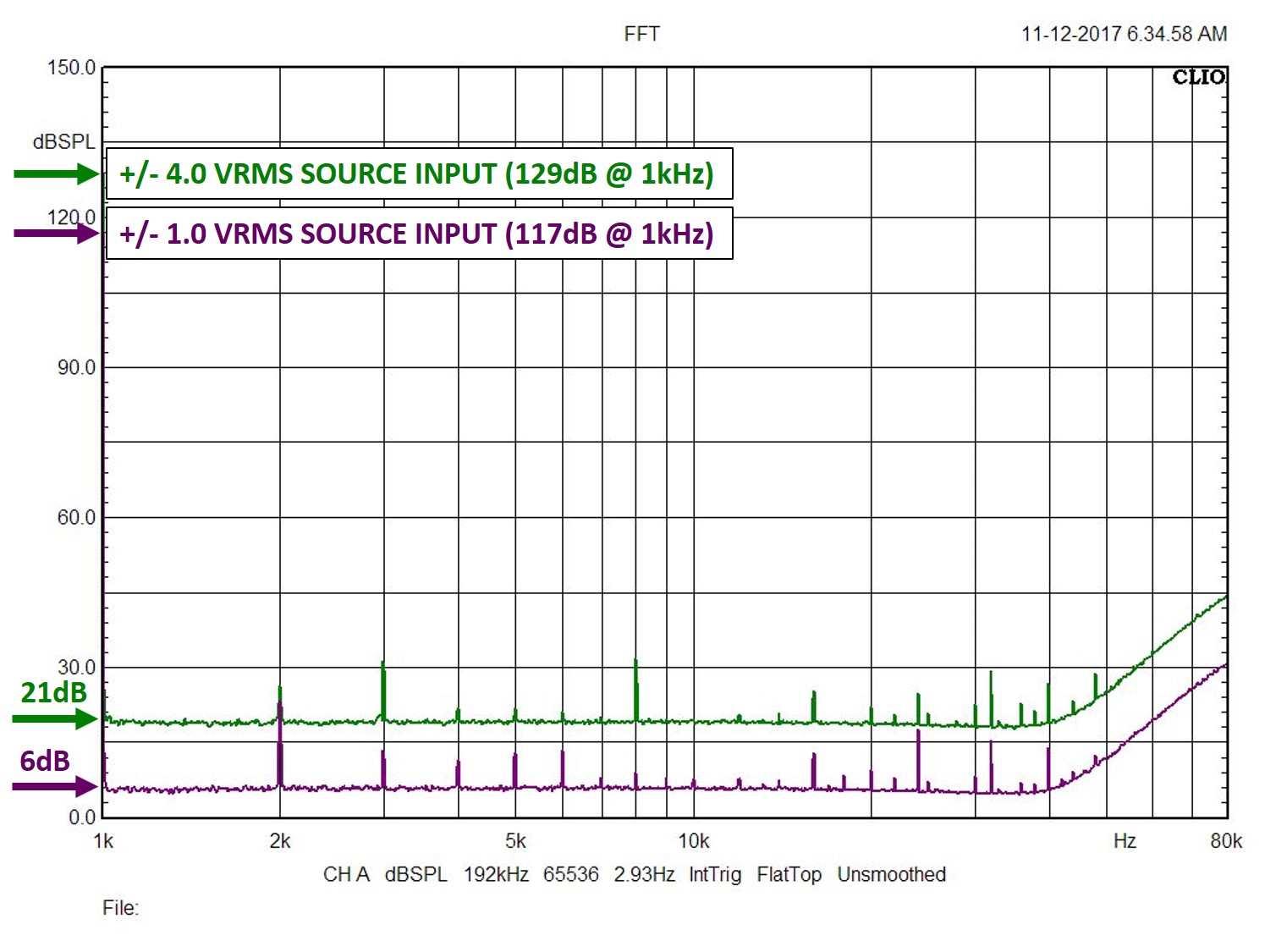

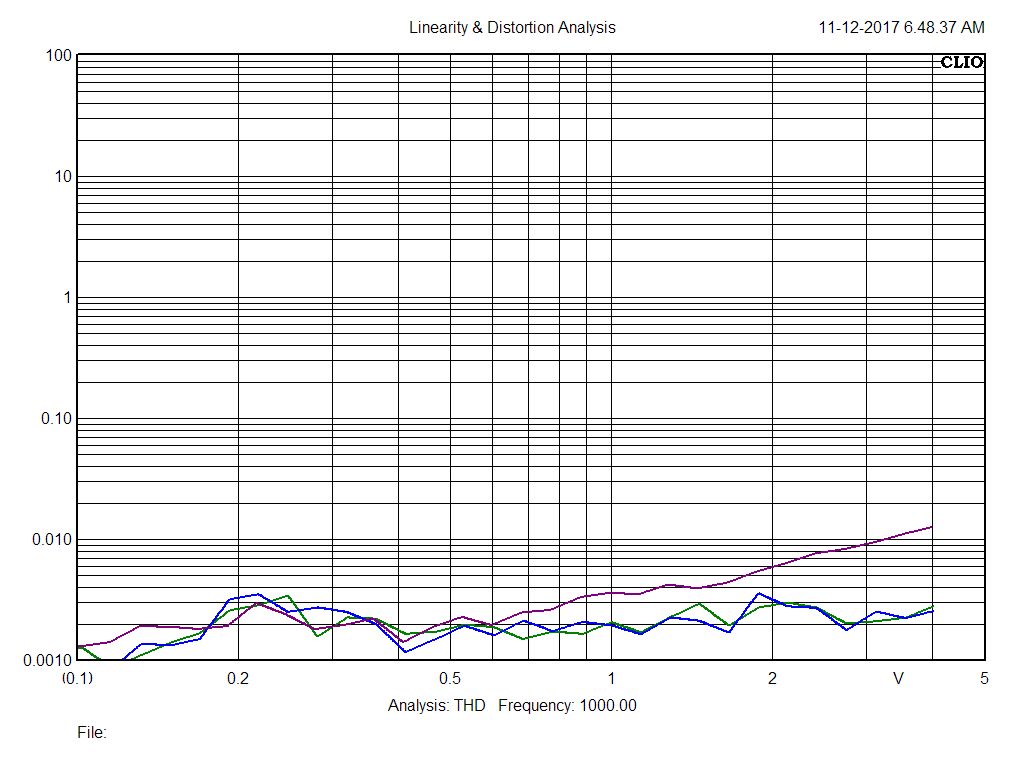

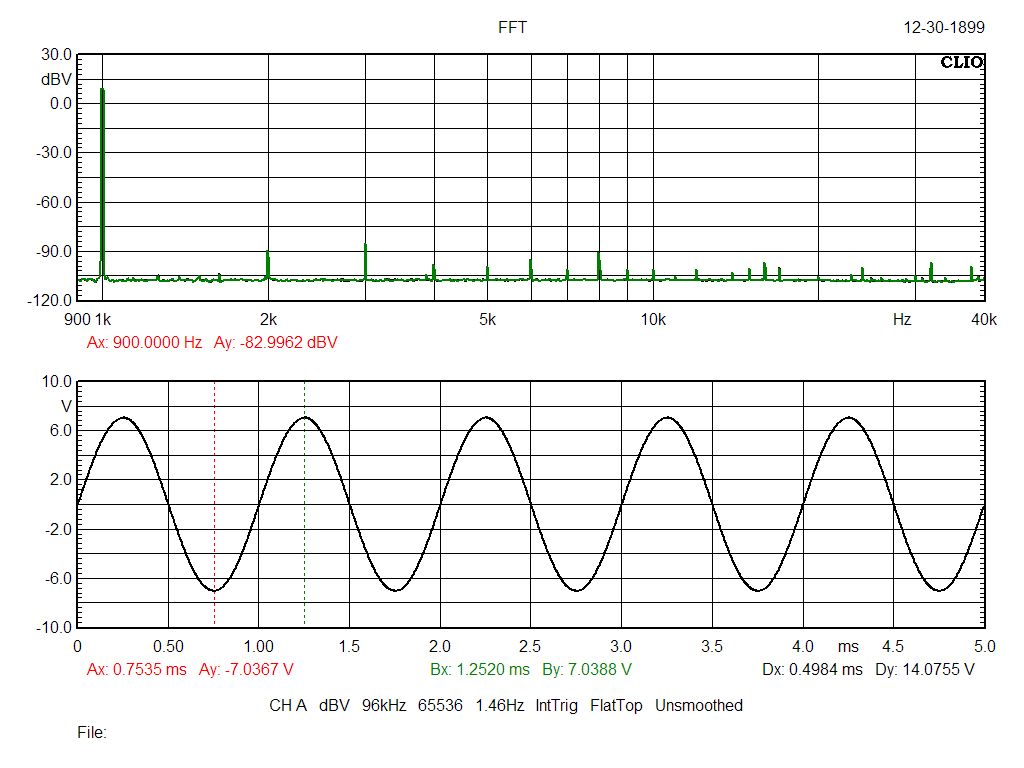

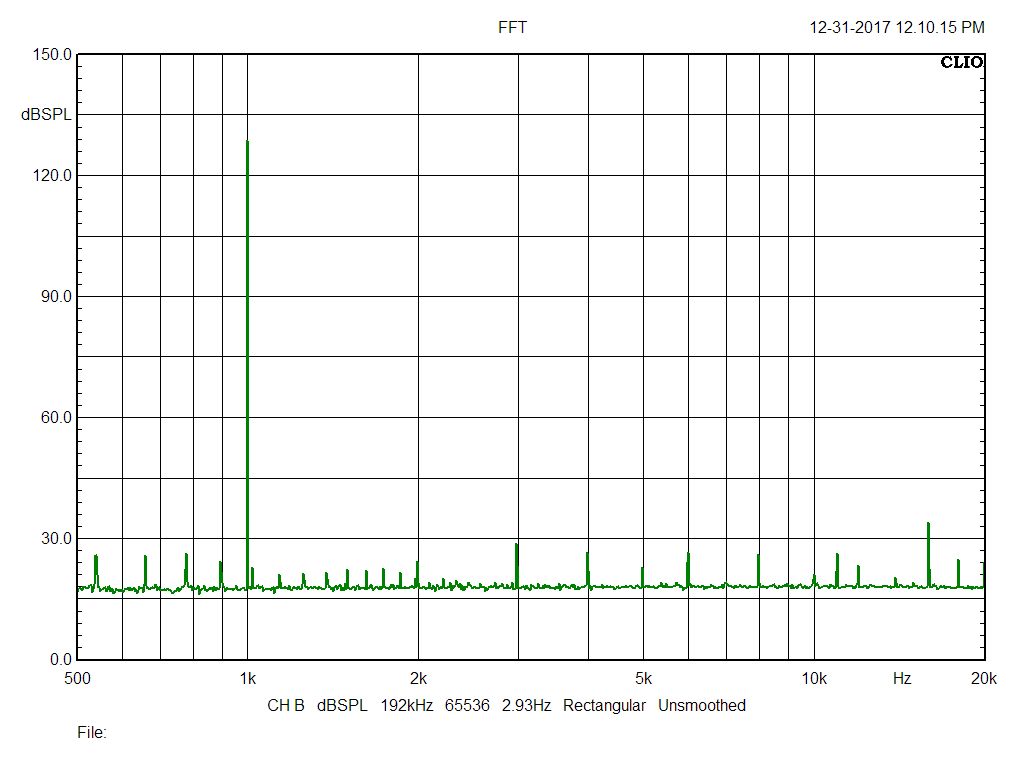

Fast Fourier Transform (FFT) of buffered output at two input levels, all outputs at RL=10k Ohm, balanced input. FFT at 192kHz sampling rate, flat-top windowing. Small differences in harmonic content is shown but overall, %THD is very low as is evidenced in the second plot showing % THD at three frequencies, 1.0kHz (green), 6.6kHz (purple) and 10kHz (blue).

BALANCED INPUTS

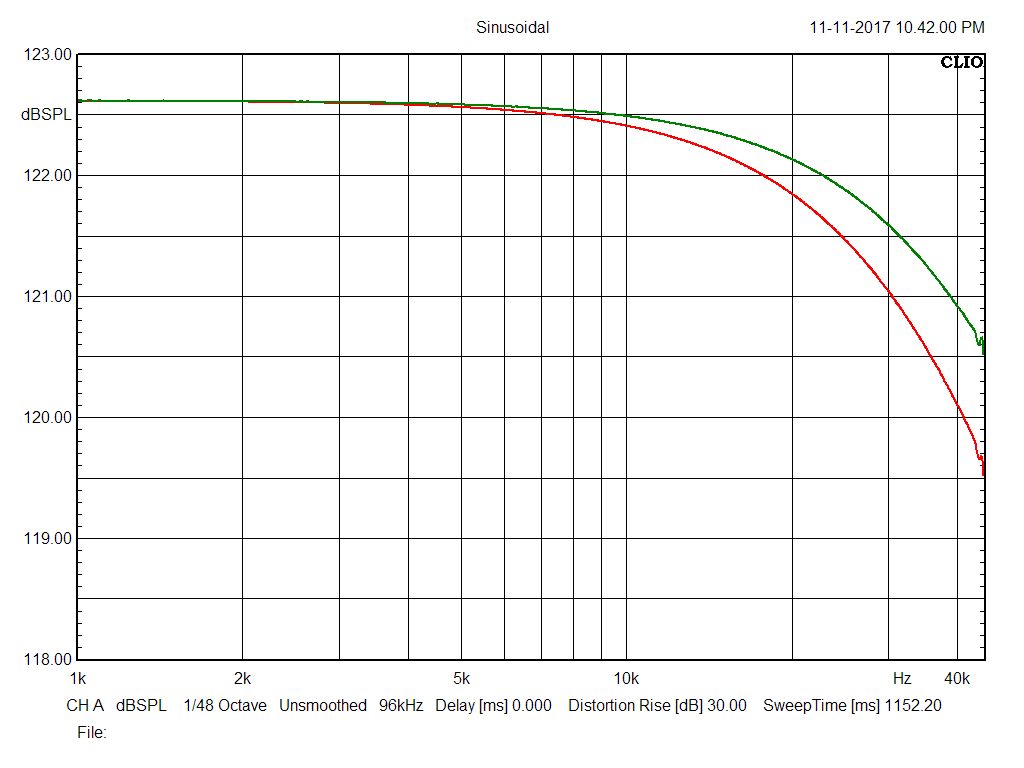

Bandwidth from 1kHz to just over 40kHz of both the buffer output (red) measured at the output terminal and differential mode filter (green) are shown below. To make the bandwidth comparison easier to interpret, the differential mode bandwidth plot was shifted "up" in dB to coincide with the buffered output plot at 1kHz. With the input filtering shown in the schematic, the 20kHz, -3db frequency of the buffered output and differential mode filter are -1.6 and -1.0dB relative to the input signal, respectively. As shown below, a +/-7.0Vp-p output swing with balanced, 1kHz input evidences very low harmonic content to 40kHz (<0.003%THD). The circuit draws about 35mA from the external supply. Output terminal block connections are direct to the op-amp output pins.

UNBALANCED INPUTS

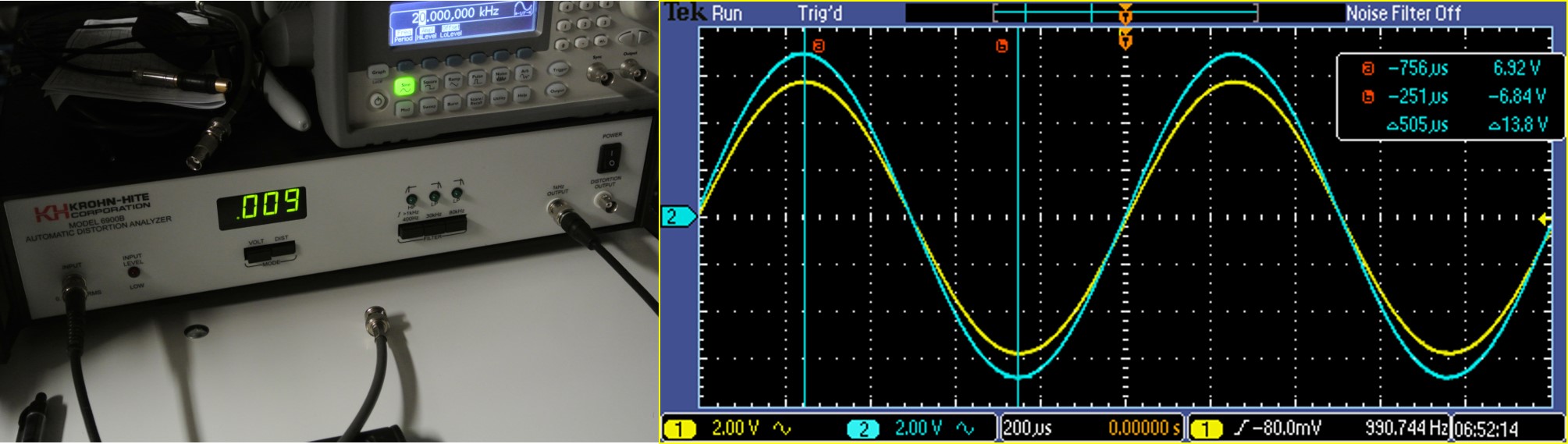

Shown below are scope traces of an unbalanced, 1kHz test signal from the internal calibration generator of the Krohn-Hite 6900B distortion analyzer being used to measure %THD at the buffer output. The source impedance of the analyzer is 600 Ohms and the no-load voltage is 14.2Vp-p or 5.0Vrms. The blue trace is the generator output voltage loaded with the buffer, measured between the XLR1 connector Pin 2 (13.8Vp-p or 4.9Vrms) and circuit ground reference. The buffer output (yellow trace) is with a 560 Ohm load across the op-amp output pin (11.5Vp-p or 4.1Vrms). Using this data, buffer unbalanced input impedance is calculated to be 16kOhm. Distortion is 0.009% THD, all analyzer filters out. Note the 6900B is capable of measuring distortion components to 1MHz.

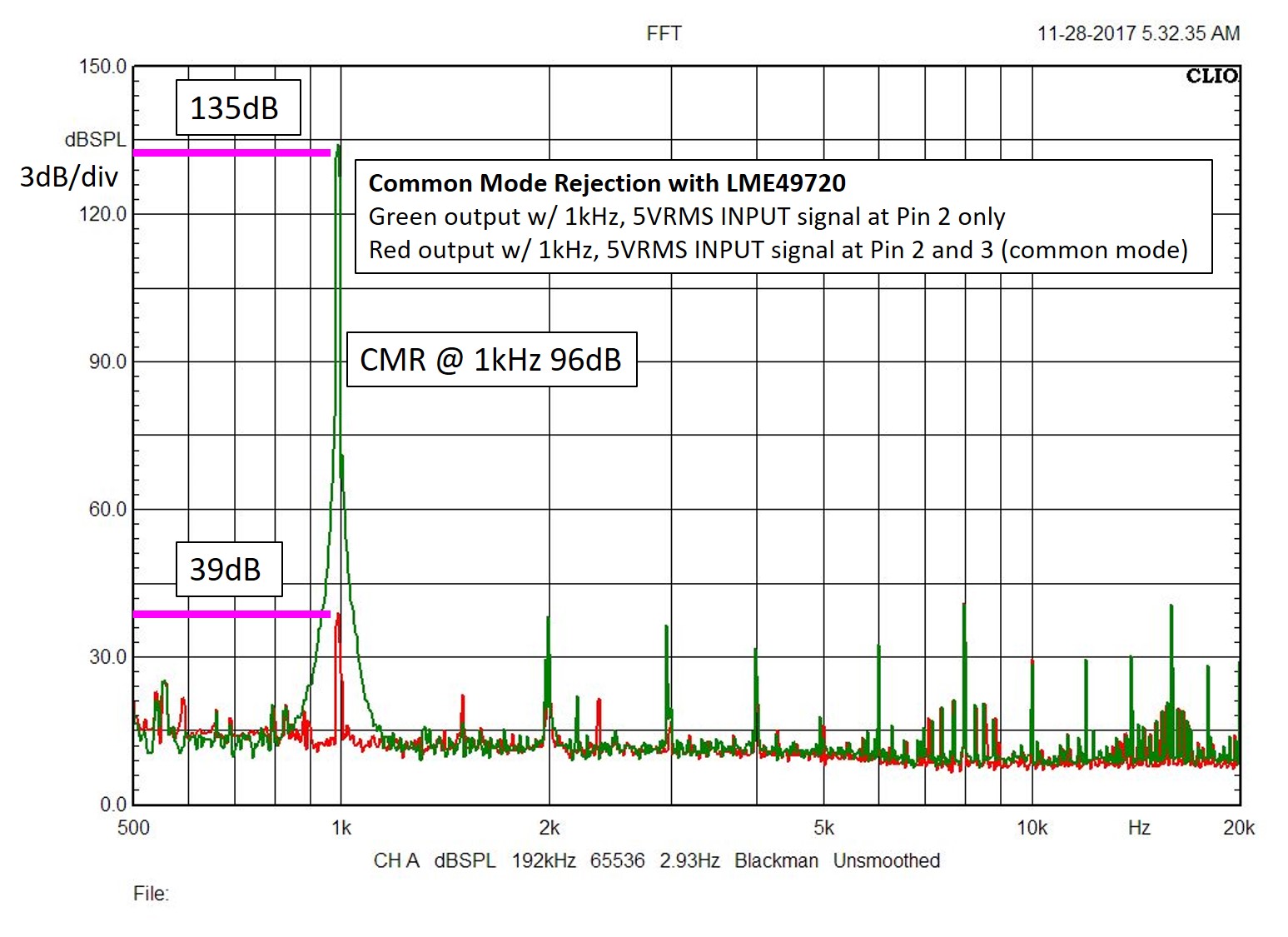

COMMON MODE REJECTION

The red plot below is the FFT response at the output of one channel with a 5VRMS amplitude, 1kHz sine wave input signal (0.002%THD) applied to both the inverting (Pin 2) and non-inverting (Pin 3) inputs. The green FFT is the output of the same channel with the input signal applied to the non-inverting input (Pin 2 alone). As shown, the common mode rejection of the circuit at the 1kHz input signal is >90dB. For the module under test, the resistor pairs were selected to be within +/-0.02% or better of the nominal values shown in the schematic. Note that the test setup used here, the input signal and the sampling clock of the analyzer are not synchronized so and a Blackman window was used to provide side lobe attenuation so some spectral leakage.

The module is exceedingly quiet and makes for an excellent HiFi preamplifier.

POWER SUPPLYS

For builders that intend to use the module as a stand-alone preamplifier or buffer stage for active filtering, a power supply is required. All tests and performance plots shown above were done with a Bel Power Solutions HAA24-0.6-AG, isolated, linear +/-24VDC, 0.6A power supply driving the on-board +/-15VDC supply. The Bel unit is an excellent, relatively low cost (~$70) supply cable of providing power to multiple buffer/splitter modules and active filters. It does require the user to install a fuse holder on the power plug.

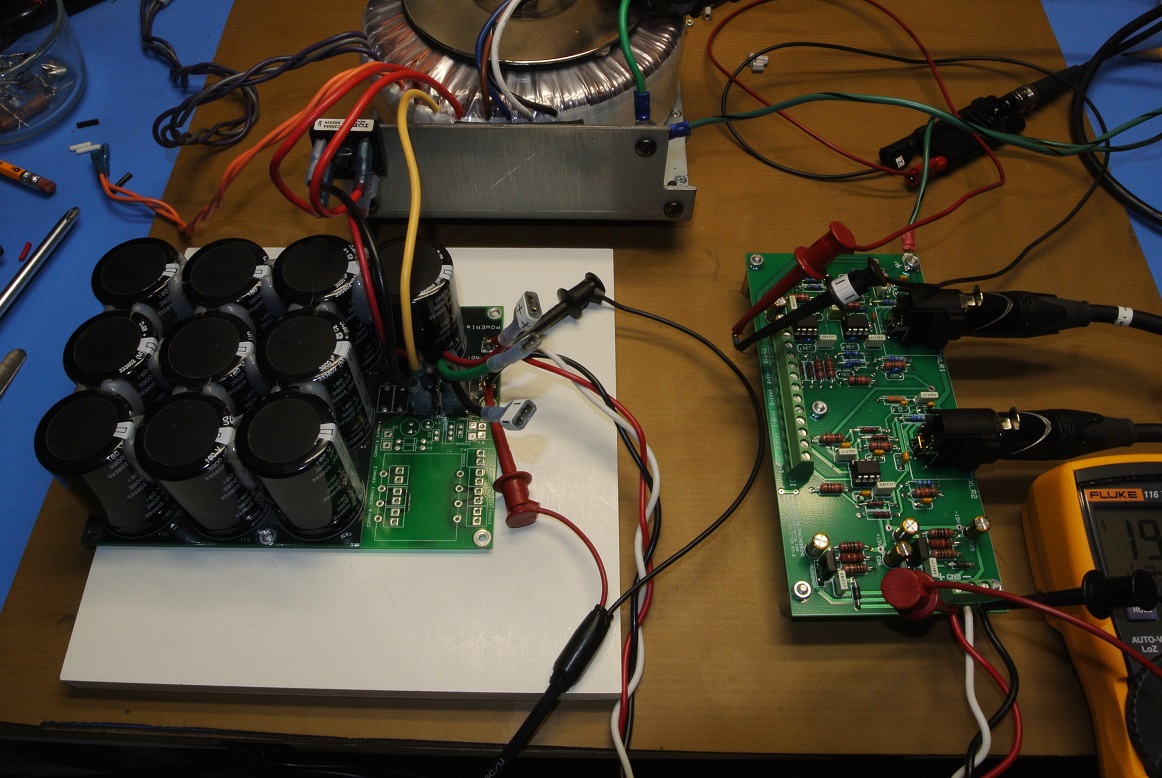

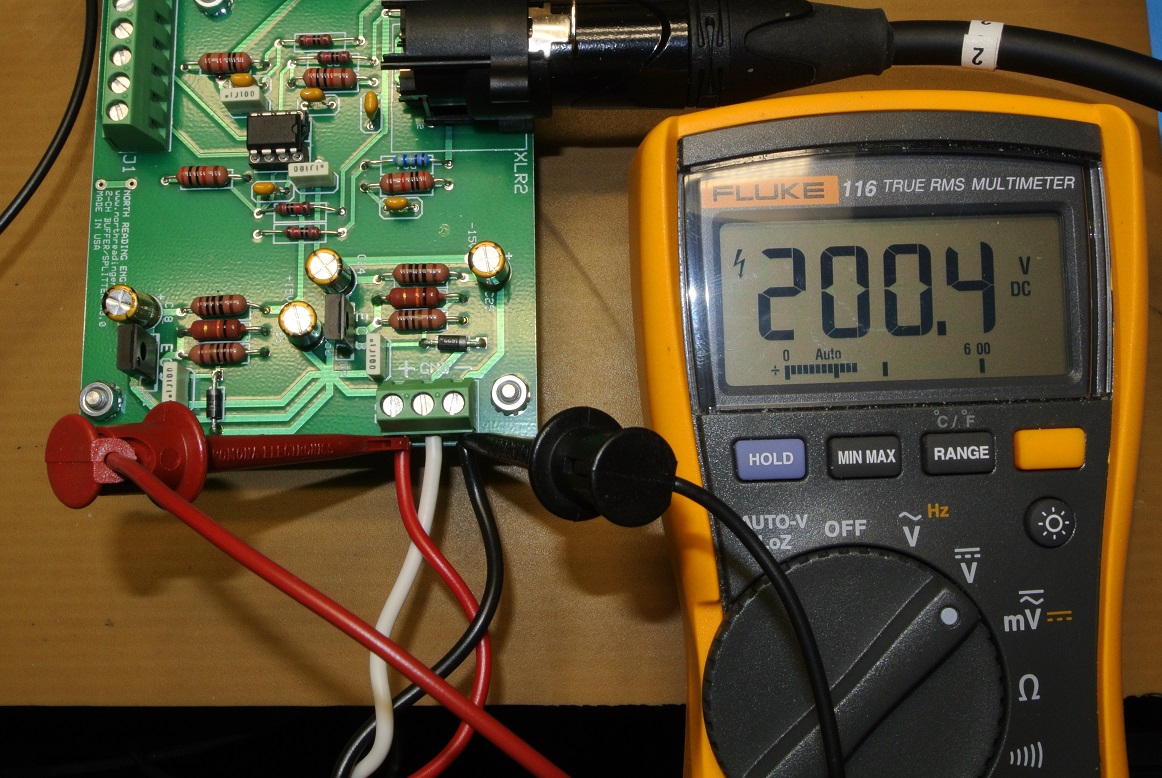

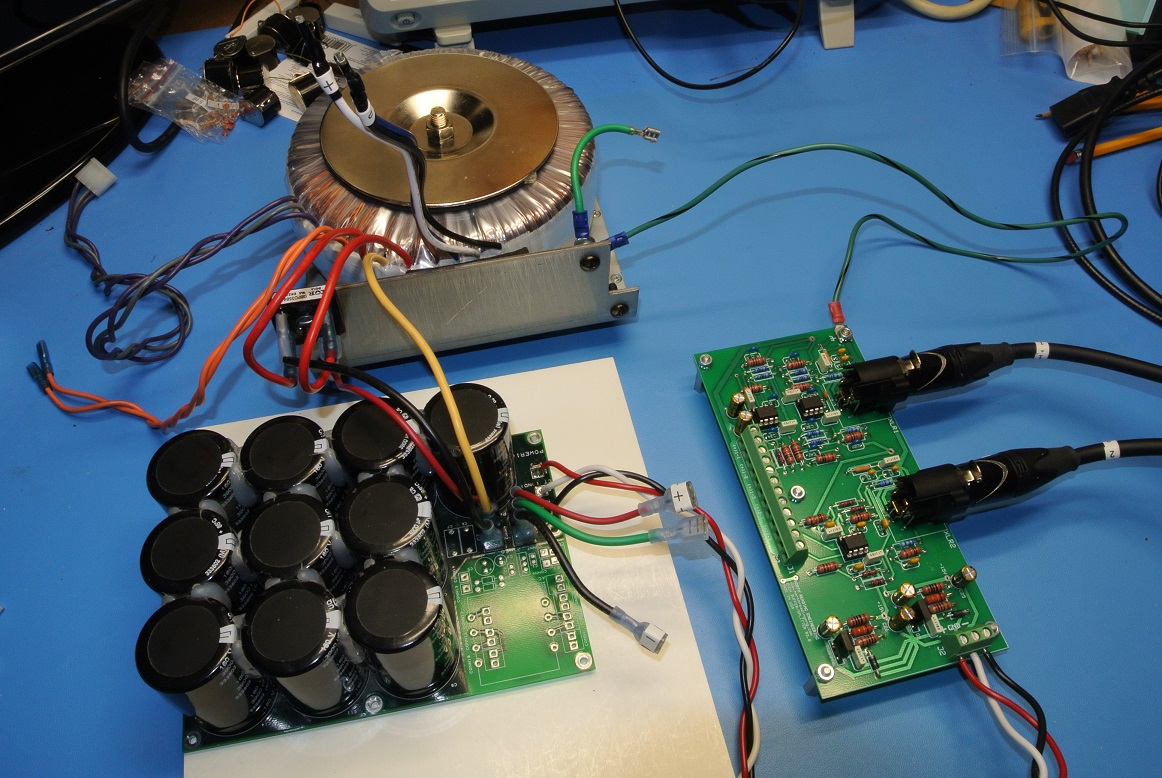

Alternatively, the board can be powered from +/- voltage taps off a conventional amplifier power supply. Shown below is a +/-100VDC supply with dedicated taps for the buffer board. The supply is a conventional +/-100VDC supply consisting of a toroidal transformer with center-tapped secondary feeding a bridge rectifier and a 40,000uF bank of filter capacitors. With a +/-100VDC supply, the MJE350/340 power transistors reach a steady state temperature of just under 140°C (max. specified 150°C). Resistors in the on-board supply are 2W.

Below, the demonstrator capacitor board has +/- taps for the buffer (R/W/B leads) and separate Faston taps to provide power to the amplifier(s). North Reading Engineering is currently designing a filter capacitor board specifically for amplifier builders interested in building their own high powered amplifiers (inquire).

FFT of CH1 output with RL=560Ohm, +/-100VDC supply, 1VRMS,1kHz balanced input signal. First plot to 80kHz, second between 500-20kHz.

SUMMARY

If you have interest in either purchasing or building the R3.0 Buffer/Splitter Module please contact North Reading Engineering. If you have an application in mind and would like to discuss if the module will work in that application, just send an email (below) and I'll be glad to discuss the application with you.

PRICING

1. Assembled R3.0 Buffer/Splitter Module, (5) Aluminum standoffs, performance data emailed to customer: $189

2. R3.0 Buffer/Splitter Kit includes one PC Board, (1) 12 and (1) 3-Position Phoenix Contact Terminal Blocks, (2) Neutrik NCJ6FAH XLR Combination Female Connectors, (3) Mill-max 8-Pin Sockets, (3) LME49720 Dual High Performance, High Fidelity Op-Amps, (1) NPN/PNP Complementary pair MJE350G/340G Power Supply Transistors, (5) Aluminum standoffs and parts list: $99

3. R3.0 Buffer/Splitter PC Board (made in USA), (5) Aluminum standoffs and parts list: $39

R3.0 Buffer/Splitter Modules and Si devices are ESD sensitive and shipped in ESD protective packages.

This webpage and its contents are the property of John Warren of North Reading Engineering, North Reading, MA 01864 USA. No part of the above work may be copied and published, in part or in total, without written permission.

© 2017 John Warren